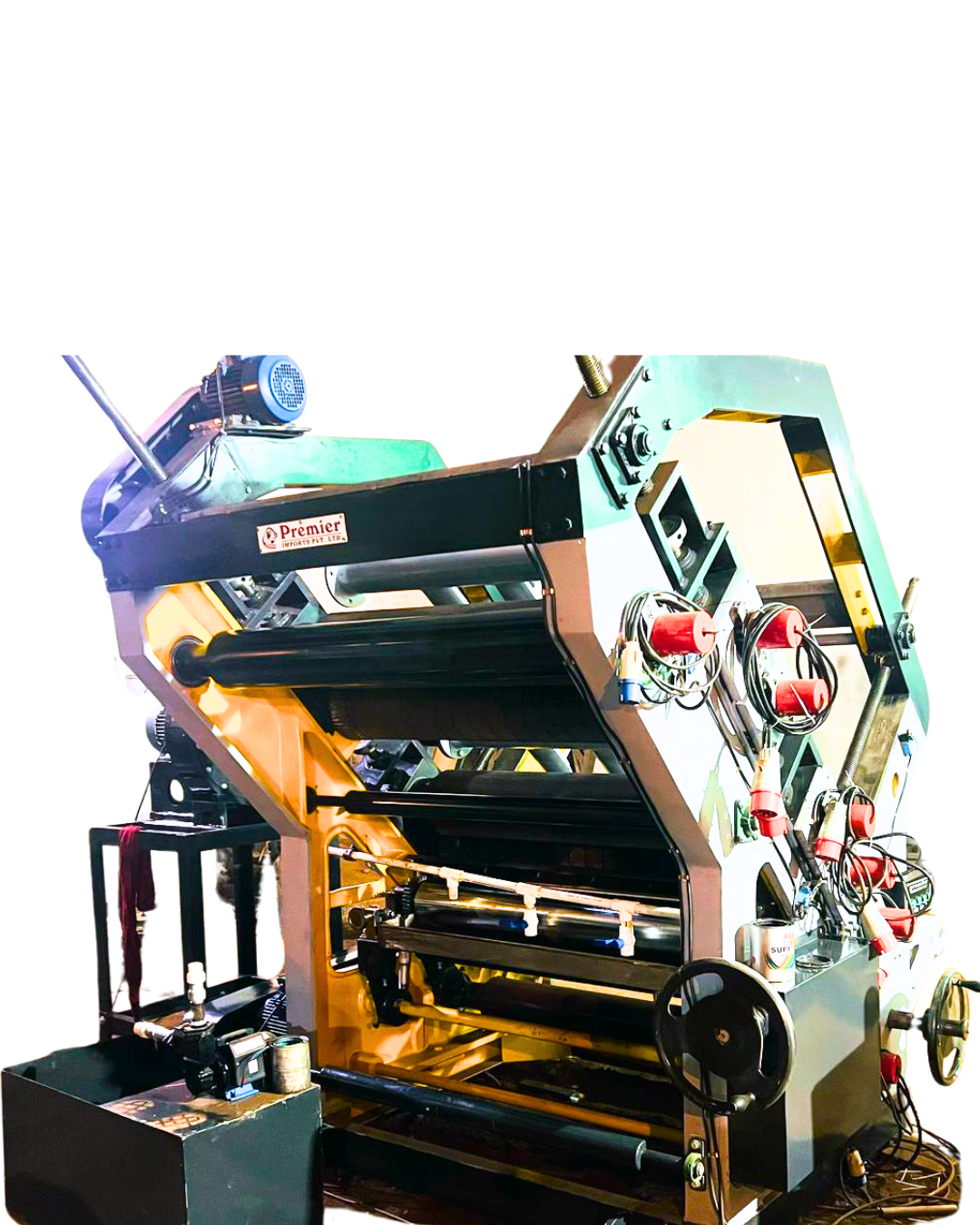

The Double Profile Corrugation Machine from Premier Imports Private Limited is a state-of-the-art solution designed to enhance the productivity and flexibility of corrugated sheet manufacturing. This advanced machine allows operators to seamlessly switch between two different flute profiles without stopping production, making it an ideal choice for packaging manufacturers that require versatility in their corrugation process.

Built with precision engineering and high-speed capability, this machine ensures uniform, strong, and durable corrugated sheets, catering to a wide range of packaging needs. Its heavy-duty construction and user-friendly operation make it a must-have for businesses looking to optimize their production efficiency while maintaining premium quality standards.

Key Features of the Double Profile Corrugation Machine

1. Dual Profile Functionality for Maximum Versatility

- Equipped with two sets of corrugating rollers, allowing instant switching between different flute profiles (A, B, C, E, etc.) without halting operations.

- Eliminates the need for multiple machines, reducing space requirements and operational costs.

- Ideal for businesses catering to varied packaging demands, from lightweight cartons to heavy-duty shipping boxes.

2. High-Speed Production for Increased Output

- Designed for continuous, high-speed manufacturing, maximizing throughput while minimizing lead times.

- Ensures seamless integration into automated production lines, reducing manual handling.

- Enhances workflow efficiency, making it ideal for high-volume production environments.

3. Precision Corrugating Rollers for Uniform Quality

- Rollers are made from hardened, high-grade steel to maintain consistent flute shapes and superior durability.

- Provides perfect adhesion between the liner and flute, resulting in stronger, more reliable corrugated sheets.

- Ensures flawless fluting with uniform wave structures, meeting industry standards for strength and flexibility.

4. Heavy-Duty Construction for Long-Term Reliability

- The machine is built with a rugged metal frame and industrial-grade components, ensuring stability and longevity.

- Withstands continuous high-speed operations, making it suitable for 24/7 production cycles.

- Reduces machine wear and tear, ensuring low maintenance costs and long-term operational reliability.

5. User-Friendly Operation with Quick Profile Switching

- Features an intuitive control panel that allows effortless switching between flute profiles.

- Reduces downtime by eliminating the need for manual adjustments.

- Designed for easy operation, making it accessible to both experienced and new operators.

6. Integrated Heating System for Stronger Adhesion

- Ensures proper bonding between the liner and corrugated medium, enhancing sheet strength.

- Provides even heating distribution, reducing delamination risks.

- Optimized for energy efficiency, lowering overall production costs.

7. Low Maintenance for Long-Term Cost Savings

- Requires minimal servicing, ensuring consistent performance with fewer disruptions.

- Designed for easy access to critical components, making maintenance straightforward.

- Reduces operational downtime, leading to higher efficiency and cost-effectiveness.

Applications of the Double Profile Corrugation Machine

1. Corrugated Box Manufacturing

- Produces high-quality corrugated sheets that serve as the base material for cartons, shipping boxes, and packaging containers.

- Allows manufacturers to switch between flute profiles based on strength and flexibility requirements.

- Suitable for both light-duty retail packaging and heavy-duty industrial packaging.

2. Custom Packaging Solutions

- Perfect for manufacturers offering specialized corrugated packaging with unique flute combinations.

- Supports custom branding, ensuring distinctive and premium packaging solutions.

- Allows for the creation of strong, lightweight, and cost-efficient packaging materials.

3. High-Volume Production Environments

- Designed for factories and printing houses that require continuous, large-scale production.

- Handles bulk orders efficiently, ensuring faster lead times and increased profitability.

- Ideal for e-commerce, logistics, and supply chain industries where high-speed production is crucial.

4. Commercial Printing and Packaging Units

- Enables customized corrugated sheets for advertising, promotional packaging, and display boxes.

- Supports offset and digital printing applications, allowing for high-end, visually appealing packaging solutions.

- Ensures smooth, flat surfaces, making it perfect for branding, printing, and lamination.

5. Food and Beverage Packaging

- Used in manufacturing food-grade corrugated packaging for takeout boxes, bakery packaging, and beverage carriers.

- Ensures moisture-resistant, durable, and safe packaging for perishable items.

- Supports eco-friendly and biodegradable packaging production.

Benefits of Using the Double Profile Corrugation Machine

1. Versatility for Multi-Purpose Production

- Offers the ability to produce corrugated sheets with different flute profiles, catering to various packaging needs.

- Eliminates the need for multiple machines, reducing space and operational costs.

- Ensures flexibility in handling different packaging types and designs.

2. Increased Efficiency & Productivity

- Quick switching between profiles eliminates downtime, resulting in higher throughput.

- High-speed production capability ensures faster turnaround times for bulk orders.

- Reduces manual intervention, leading to optimized labor costs and enhanced production efficiency.

3. Consistent Quality with Precision Engineering

- Delivers uniform corrugated sheets with accurate fluting, ensuring superior product quality.

- Provides exceptional strength and durability, meeting packaging industry standards.

- Enhances customer satisfaction with high-quality, defect-free corrugated sheets.

4. Cost-Effective & Space-Saving Design

- Dual flute profile functionality eliminates the need for additional machines, saving floor space.

- Energy-efficient heating system lowers operational costs while ensuring stronger adhesion.

- Low maintenance requirements reduce long-term servicing expenses.

5. Safe and Secure for Operators

- Designed with safety mechanisms to prevent accidents and operator injuries.

- Emergency stop features ensure immediate shutoff in case of malfunctions.

- Meets industrial safety standards, providing a secure working environment.

Why Choose the Double Profile Corrugation Machine from Premier Imports Private Limited?

At Premier Imports Private Limited, we specialize in providing high-quality industrial machinery designed for efficiency, durability, and innovation. Our Double Profile Corrugation Machine is a powerful, high-speed solution that enhances production efficiency while maintaining impeccable quality.

What Makes Us Stand Out?

Dual Profile Capability – Instant switching between two flute types.

High-Speed Production – Handles bulk manufacturing effortlessly.

Heavy-Duty Construction – Built for 24/7 industrial operations.

Energy-Efficient – Optimized heating system for better adhesion and cost savings.

Expert Support & Training – Backed by professional guidance and technical assistance.

Enhance Your Corrugated Sheet Production with Premier Imports Private Limited!

The Double Profile Corrugation Machine is the ultimate solution for manufacturers seeking versatility, efficiency, and superior quality in corrugated sheet production. Whether you’re producing custom packaging, bulk cartons, or premium branded packaging, this machine will revolutionize your manufacturing process.

💡 Contact us today to discover how our Double Profile Corrugation Machine can streamline your production and elevate your packaging business!